6 products

Heat Press Equipment

Heat Press Equipment for Tee Shirts, Polo Shirts, Windcheaters, Hoodies and more....

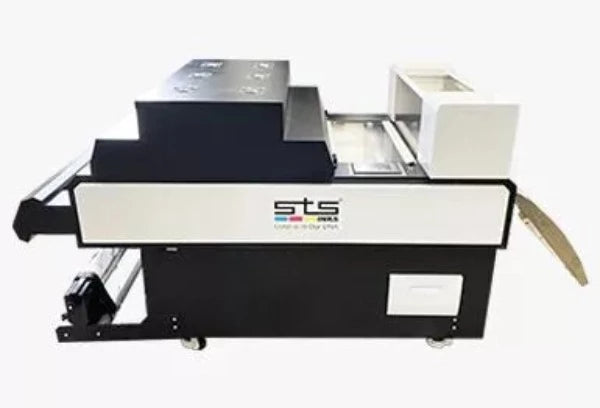

Perferct for all types of applications from Sublimation prints, DTF - Direct to Film, DTG - Direct to Garment and Heat Seal Vinyls

When selecting a commercial garment heat press for transfer printing, several features are important to consider for efficiency, quality, and ease of use:

- Size and Type of the Heat Press: The size should be appropriate for the types of garments and transfers you plan to use. Common sizes range from 38x38 cm to 40x50 cm. There are various types like clamshell, swing-away, and draw heat presses, each with their own advantages. Clamshell models are space-saving and easier to use, swing-away models provide better access and pressure distribution, and draw models combine some benefits of both.

- Adjustable Pressure and Even Heat Distribution: Uniform pressure and consistent heat are crucial for high-quality transfers. Look for a heat press with easy-to-adjust pressure settings and a design that ensures even heat distribution across the platen.

- Temperature Range and Accuracy: A wide temperature range is important to accommodate different types of transfer materials. The heat press should also have accurate temperature control to avoid issues like under or over-curing of the transfer material.

- Digital Timer and Temperature Controls: Digital controls for time and temperature settings provide precision and ease of use. Multi-timer allows the user to preset individual time settings for three steps application for pre-heating (moisture removal), print application and softerning/finishing press. They allow for consistent results, which is especially important for commercial production.

- Interchangeable Platens: Having the ability to change out the lower platen can be beneficial for printing on various sized garments or on different locations of a garment, like sleeves or pant legs.

- Quality of the Build: A robust and sturdy build ensures longevity and durability, especially important in a commercial setting where the machine will be used frequently.

- Ease of Maintenance: Look for a heat press that is easy to clean and maintain. This helps in prolonging the life of the machine and ensures consistent quality in prints.

- Safety Features: Safety features such as auto shut-off, heat-resistant covers, and sound alerts are important to prevent accidents and injuries in a busy commercial environment.

- Warranty and Customer Support: A good warranty and responsive customer support are crucial for addressing any issues that may arise during usage.

- Additional Features: Some advanced presses come with features like touchscreen controls, programmable presets, or special attachments for specific applications (like cap or mug presses).

Selecting a heat press with these features will contribute to a smoother, more efficient, and high-quality transfer printing process in a commercial high production setting.